microBioprocessing Hub

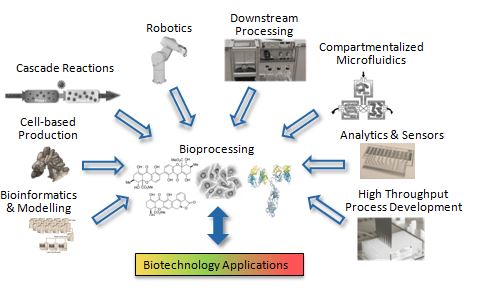

The aim of the microBioprocessing Hub is to coordinate the development of new technologies and processes for the biocatalytic synthesis, isolation and characterization of biotechnologically relevant organic compounds within compartmentalised microfluidic systems. The required “MicroBioprocess Technologies” span a broad range of disciplines from engineering and informatics to surface chemistry and biology.

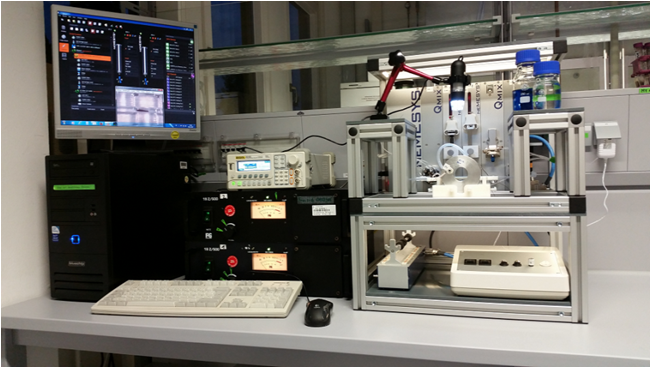

A particular focus lies on mimicking the native conditions of biocatalytic enzymes, as well as on establishing mild and efficient ways for the addition of educts and co-reactants, the separation of by-products, and the purification of desired products in continuous flow systems. The rapid development of novel bioprocess systems are enabled by the design and fabrication of tailored automated modules. These modules are manufactured by rapid prototyping using multi-material 3D printing and are compatible with commercial robotic platforms. In particular we are currently developing key components based on microfluidics on liquid handling stations. One further challenge is to develop novel approaches for integrated regulatory circuits as well as for fast and sensitive analytics. This is being complemented by the development of tools that enable the simulation of each step, starting from computational fluid dynamics to biochemical pathway modelling.

cascade microreactor (reaction volume 2.5 – 100 µl) employing magnetic carriers